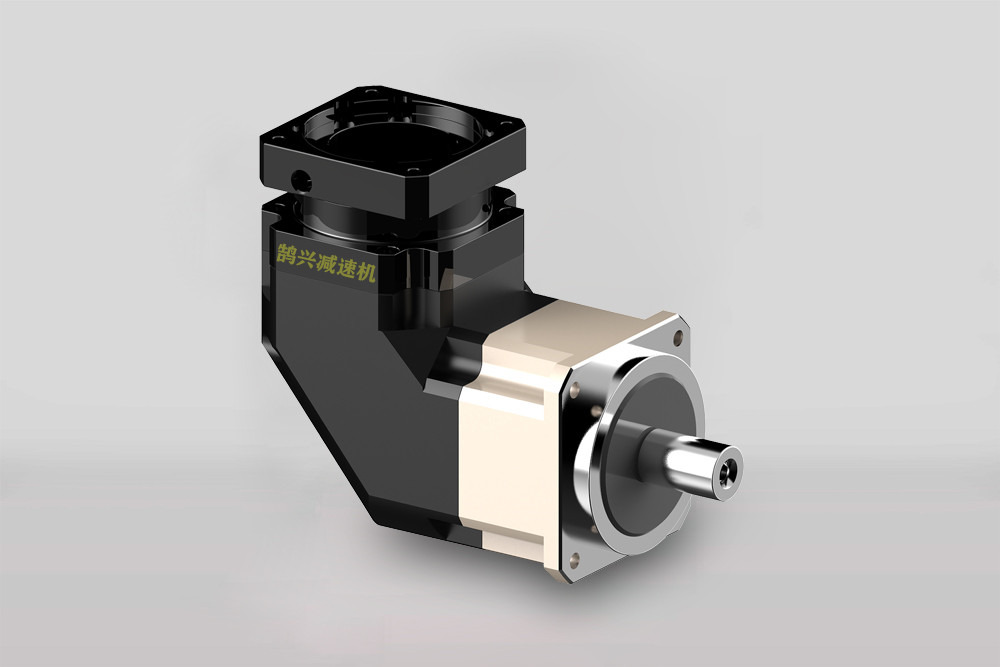

F系列減速電機的研齒JRTKF77減速器型號大全

文章出(chu)處(chu):admin 人氣:發(fa)表時間:2019-10-30 11:19

F系列減(jian)(jian)速電機(ji)的研(yan)齒(chi),JRTKF77減(jian)(jian)速器型號大(da)全平行軸(zhou)減(jian)(jian)速機(ji)的制造(zao)過程中,由于箱體的加(jia)工(gong)誤(wu)差(cha)(cha),齒(chi)輪(lun)加(jia)工(gong)誤(wu)差(cha)(cha),熱(re)處理變形以及裝配綜(zong)合誤(wu)差(cha)(cha)等,在(zai)有些情況(kuang)下,造(zao)成齒(chi)面接觸率偏低,降低了F系列減(jian)(jian)速電機(ji)的使用壽命,為了消除(chu)各類誤(wu)差(cha)(cha),提高齒(chi)面接觸率,改(gai)善齒(chi)面粗糙度,除(chu)在(zai)加(jia)工(gong)方面采(cai)取定的措施外,在(zai)裝配方面可采(cai)取研(yan)齒(chi)的方法(fa)。

F系列平行軸減速機,JRTKF77減速器型號大全

研齒(chi)(chi)(chi)(chi)前的(de)要(yao)求:F系(xi)列齒(chi)(chi)(chi)(chi)輪減速機(ji)(ji)中各(ge)轉(zhuan)動(dong)部位(包括滾動(dong)軸(zhou)(zhou)承或滑(hua)動(dong)軸(zhou)(zhou)承,軸(zhou)(zhou)頸密封等)、油路、管、孔等關鍵部位,要(yao)采取嚴密有(you)效的(de)密封措(cuo)施,避免在(zai)平行軸(zhou)(zhou)減速機(ji)(ji)研齒(chi)(chi)(chi)(chi)過程中的(de)研磨(mo)(mo)劑進入(ru)上(shang)(shang)述(shu)各(ge)部位。將齒(chi)(chi)(chi)(chi)面(mian)清洗干凈,并(bing)在(zai)四個齒(chi)(chi)(chi)(chi)上(shang)(shang)涂(tu)CT-1涂(tu)料。檢(jian)查(cha)F系(xi)列減速電機(ji)(ji)齒(chi)(chi)(chi)(chi)輪齒(chi)(chi)(chi)(chi)面(mian)接觸(chu)斑點,齒(chi)(chi)(chi)(chi)長方向達(da)到圖紙(zhi)接觸(chu)精度(du)要(yao)求,接觸(chu)部位在(zai)齒(chi)(chi)(chi)(chi)中部,齒(chi)(chi)(chi)(chi)高接觸(chu)部位應在(zai)節(jie)圓(yuan)附近,若齒(chi)(chi)(chi)(chi)或齒(chi)(chi)(chi)(chi)根接觸(chu),需用軟(ruan)質砂輪修磨(mo)(mo),消除(chu)齒(chi)(chi)(chi)(chi)或齒(chi)(chi)(chi)(chi)根的(de)接觸(chu)硬點,原(yuan)則(ze)上(shang)(shang)只允許修磨(mo)(mo)平行軸(zhou)(zhou)減速機(ji)(ji)大(da)齒(chi)(chi)(chi)(chi)輪。檢(jian)查(cha)各(ge)對齒(chi)(chi)(chi)(chi)輪副的(de)齒(chi)(chi)(chi)(chi)側間隙,要(yao)求符合圖紙(zhi)要(yao)求。檢(jian)查(cha)研齒(chi)(chi)(chi)(chi)各(ge)聯接部位,有(you)無松動(dong)現象,切要(yao)達(da)到研齒(chi)(chi)(chi)(chi)運轉(zhuan)要(yao)求。

研(yan)齒加載:就(jiu)是在(zai)F系列減速(su)電(dian)機輸(shu)出軸上加定(ding)扭(niu)矩,其(qi)作(zuo)用除保(bao)證研(yan)齒處于連(lian)續嚙合狀(zhuang)態(tai)和具備齒面(mian)有定(ding)的嚙合壓力,滿足研(yan)齒條件外。研(yan)齒負荷(he)確(que)定(ding)為平行軸減速(su)機額定(ding)負荷(he)的15%-20%。當(dang)研(yan)齒速(su)度(du)較(jiao)低,負荷(he)先偏(pian)大值(zhi);當(dang)研(yan)齒速(su)度(du)較(jiao)高,負荷(he)選偏(pian)小值(zhi),在(zai)研(yan)齒過(guo)程(cheng)中,負荷(he)必須穩(wen)定(ding),不能隨意改變。

研(yan)(yan)齒(chi)(chi)工(gong)藝過程:選擇適當的(de)(de)研(yan)(yan)齒(chi)(chi)聯接方(fang)式,先(xian)將F系列減(jian)(jian)速(su)(su)電機(ji)在試驗平臺上調(diao)平,要求水平度(du)0.05/1000mm,再與加載設備聯接并找正,要求同軸(zhou)度(du)0.01mm,然后將聯軸(zhou)器螺(luo)栓擰緊(jin),將整個裝置(zhi)用(yong)螺(luo)栓,壓板壓緊(jin)在試驗平臺上。全面(mian)清(qing)(qing)洗平行軸(zhou)減(jian)(jian)速(su)(su)機(ji)齒(chi)(chi)輪齒(chi)(chi)面(mian),保證齒(chi)(chi)面(mian)清(qing)(qing)潔(jie)干凈,齒(chi)(chi)面(mian)四個齒(chi)(chi)涂CT-2涂料,各軸(zhou)承處采用(yong)密封擋板,嚴防(fang)研(yan)(yan)磨(mo)劑濺入F系列減(jian)(jian)速(su)(su)電機(ji)軸(zhou)承。盤(pan)動(dong)高(gao)速(su)(su)軸(zhou),應轉動(dong)靈活,無異(yi)常(chang)現(xian)象,然后可以開始研(yan)(yan)齒(chi)(chi),研(yan)(yan)齒(chi)(chi)順(shun)序從低速(su)(su)到高(gao)速(su)(su),研(yan)(yan)齒(chi)(chi)速(su)(su)度(du)及加載量按(an)前面(mian)規范。當負荷、速(su)(su)度(du)確定后,控(kong)制時間即為(wei)研(yan)(yan)齒(chi)(chi)質(zhi)量和(he)效(xiao)率的(de)(de)關鍵性指標,在研(yan)(yan)齒(chi)(chi)時,研(yan)(yan)磨(mo)劑涂刷均勻(yun)后,對研(yan)(yan)跑合5-10分應停車檢查(cha)研(yan)(yan)磨(mo)齒(chi)(chi)面(mian)的(de)(de)接觸(chu)的(de)(de)情(qing)況,掌握其發(fa)展趨勢,然后針對減(jian)(jian)速(su)(su)箱應用(yong)實情(qing)再進行研(yan)(yan)齒(chi)(chi),直到研(yan)(yan)齒(chi)(chi)合格(ge)為(wei)止。

研齒結束(shu)后,對齒輪(lun)沿齒長方向兩端(duan)研磨后的遺留(liu)凸臺修磨平(ping)滑;將平(ping)行軸減(jian)速(su)機(ji)齒輪(lun)齒面清洗(xi)干凈,涂著色劑(ji)輕微制動,用(yong)透(tou)明膠帶粘取齒輪(lun)接觸(chu)印跡;進行全面、仔(zi)細清洗(xi),確(que)保(bao)清潔。清洗(xi)液可選用(yong)煤油或各(ge)類清洗(xi)劑(ji)。通過研齒的F系列減(jian)速(su)電機(ji)噪聲,壽命(ming)指標(biao)有(you)明顯改善,客戶投訴明顯減(jian)少(shao)了。

F系列(lie)平行軸減(jian)速機,JRTKF77減(jian)速器(qi)型(xing)號大全(quan)

此文關鍵(jian)字:JRTKF77減速器型號大全,F系列減速電機

同類文章排行

- 浙江瑞德森減速機安裝尺寸圖紙資料選型樣本

- 泰興泰隆減速機型號大全及銷售售后電話使用說

- 泰興華東減速機圖紙選型手冊資料樣本

- 浙江飛龍減速機型號參數規格選型手冊

- 怎樣合理選擇擺線減速機的配套機架

- 影響回轉減速機軸與滾筒軸的 壽命因素

- 影響減速機承載能力的 因素

- 引起減速機溫升過大的 原因

- 教你三下五除二解決行星減速機工作后溫度很高

- 99%的人都不知道行星減速機的減速比計算方式

最新資訊文章

- 教你三下五除二解決行星減速機工作后溫度很高

- 99%的人都不知道行星減速機的減速比計算方式

- 高端玩家是怎么選擇齒輪減速機的?

- 如何掌握擺線針輪減速機磨合期注意事項

- 免費贈送-行星齒輪減速機用油注意事項

- 好消息各種提高行星減速電機承載能力的途徑介

- 保證看了你會更想知道行星減速機的優點?

- 等你來挑戰-污水處理設備GK系列齒輪減速機電機

- 博能減速機型號聯系電話選型手冊資料樣本下載

- 驚呆了微型行星減速機小直徑行星齒輪減速機廠

- 無錫江蘇廣東上海直角斜齒精密行星減速機廠家

- 機密資料進口行星減速機品牌和生產廠家聯系電

- 東方信濃雷塞鳴志57 86 130步進電機行星減速機尺

- 看完這些照片,瞬間秒懂斜齒行星減速機的選型

- 看完了,你就甩別人一條街(精密伺服行星減速

- 精密高精密進口直角硬齒面江蘇行星減速機廠家

- 深圳行星齒輪減速機生產廠家行星減速機生產商

- 上海行星齒輪減速機廠家聯系電話趕緊收藏了

- 深圳直角L型行星減速機廠家與轉角拐角90度減速

- 純干貨臺灣行星減速機與臺灣精密行星減速機品

SBD申克稱電子秤專用擺線' />

SBD申克稱電子秤專用擺線' />